Filters are crucial in environments that demand high purity levels, such as in factories, hospitals, and power plants. Achieving pure gas or liquid outputs necessitates impeccable sealing of filter frames to maintain the system's effectiveness.

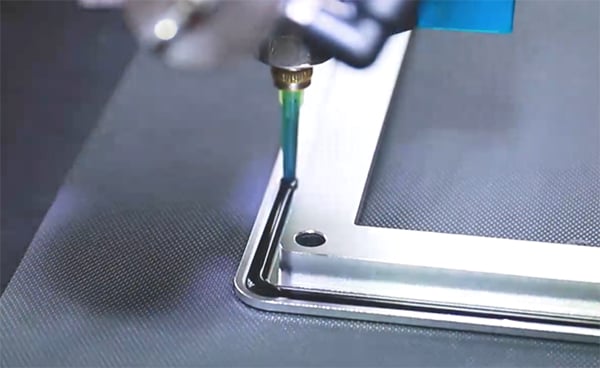

Our form-in-place gasketing machinery facilitates a seamless integration of filter components and frames, preventing leaks and ensuring resilience against harsh chemicals and high temperatures, thus delivering superior sealing and gasketing outcomes.

To complement this, our mixing and metering systems are engineered for flexible integration within existing production setups. With the support of CNC multi-axis programming, they provide pinpoint accuracy and efficient repositioning and metering capabilities, streamlining the production process and enhancing performance.

How can we help You?

Suitable for various gasket sealants and adhesives with different properties, the three-component drum pump supply system features simple and user-friendly design and exceptional flexibility of meeting various gasketing demand.

The automatic drum dispensing system can accommodate up to 55 gallons (approximately 200 kg of materials), featuring automatic cover lifting and an automated system for feeding, stirring, and supplying materials, all powered pneumatically for energy efficiency.

Leveraging our extensive expertise in formed-in-place foam gasket equipment manufacturing, we specialize in creating bespoke automatic gasketing & sealing lines. These are fully customizable to match your specific requirements in terms of travel range, gasket width, pace, and foam gasket type, etc., ensuring a solution that is perfectly aligned with your production goals.