In the photovoltaic and solar industry, our formed-in-place foam gasket machine plays a constructive in sealing PV modules, safeguarding them against water, dust, and extreme weather conditions. Our formed-in-place mixing and dosing system addresses your concerns regarding material quality, technological advancements, adaptability, cost-effectiveness, and overall performance efficiency. Additionally, we provide dependable sealing solutions for the PV industry, focusing on enhancing the performance and extending the lifespan of PV modules.

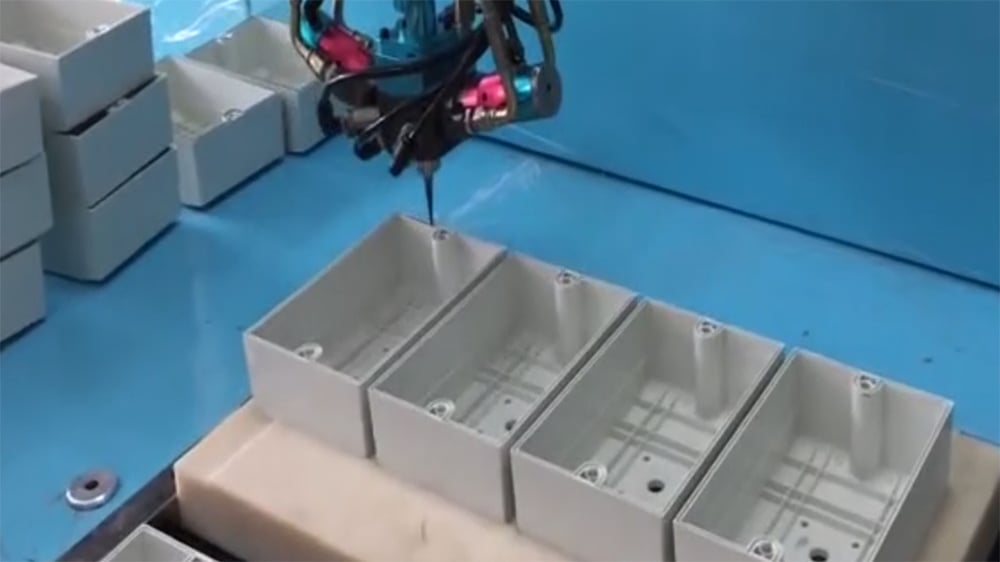

Our automatic mixing and metering system can apply polyurethane foam gaskets onto PV control cabinets with exceptional precision. Thanks to the high viscosity of our foam gasket, it can be dispensed steadily and accurately, ensuring a flawless assembly effect and securing the cabinets against water penetration. This automation not only enhances operational efficiency but also ensures the reliability and precision of the sealing process, making it an ideal tool for maintaining the integrity of PV control systems.

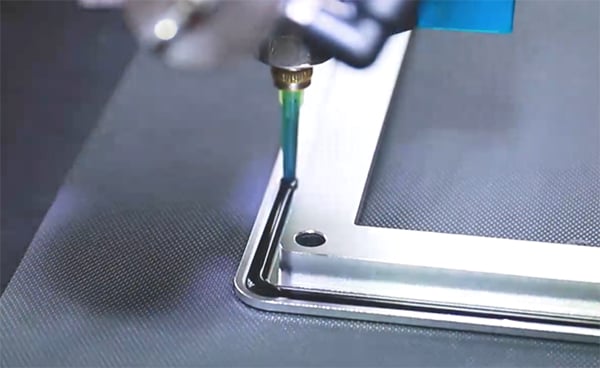

Our precise and stable gasketing machine operates seamlessly in narrow grooves, making it perfectly suited for intricate workpieces. The gasketing process ensures that sealed items are thoroughly protected against moisture, corrosion, and dust.

How can we help You?

Suitable for various gasket sealants and adhesives with different properties, the three-component drum pump supply system features simple and user-friendly design and exceptional flexibility of meeting various gasketing demand.

The automatic drum dispensing system can accommodate up to 55 gallons (approximately 200 kg of materials), featuring automatic cover lifting and an automated system for feeding, stirring, and supplying materials, all powered pneumatically for energy efficiency.

Leveraging our extensive expertise in formed-in-place foam gasket equipment manufacturing, we specialize in creating bespoke automatic gasketing & sealing lines. These are fully customizable to match your specific requirements in terms of travel range, gasket width, pace, and foam gasket type, etc., ensuring a solution that is perfectly aligned with your production goals.