Polyurethane foam-in-place gasketing machine (5-30mm) is a split system independently designed and produced by SHANJIA. It features an instant nozzle-closing mechanism to prevent material drips and blockages, alongside automated cleaning and pressure control functionalities. Its mixing chamber's modular design simplifies maintenance and minimizes reliance on quick-wear parts. Furthermore, the inclusion of globally sourced, high-quality components enhances the formed-in-place gasket machine's overall stability, making it a robust solution for a wide range of gasketing and sealing applications.

Learn More Company Profile

Company Profile

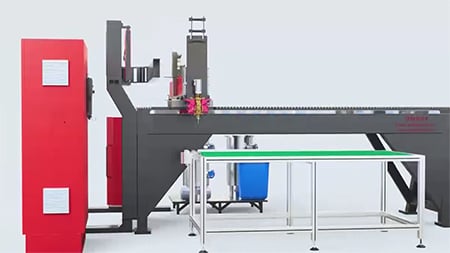

SJ-503 (5-30mm) Formed-in-Place Foam Gasket Machine

SJ-503 (5-30mm) Formed-in-Place Foam Gasket Machine

SJ-403-1 (5-30mm) Formed-in-Place Foam Gasket Machine

SJ-403-1 (5-30mm) Formed-in-Place Foam Gasket Machine

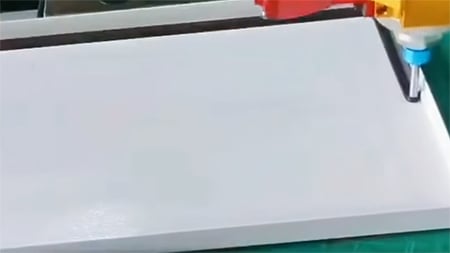

SJ-304-1(2-10mm) Formed-in-Place Foam Gasket Machine

SJ-304-1(2-10mm) Formed-in-Place Foam Gasket Machine

SJ-304-2(3-15mm) Formed-in-Place Foam Gasket Machine

SJ-304-2(3-15mm) Formed-in-Place Foam Gasket Machine

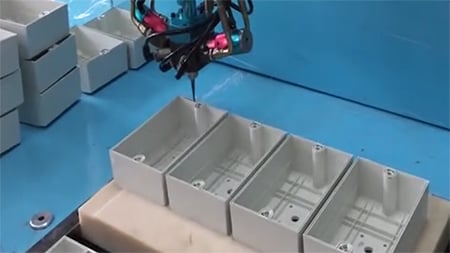

Six Axis Robot Adhesive Dispensing System

Six Axis Robot Adhesive Dispensing System

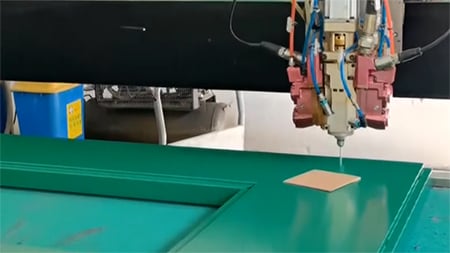

Automatic Shuttle Table

Automatic Shuttle Table

Automatic Gasketing Sealing Line

Automatic Gasketing Sealing Line

Automotive

Automotive

Electrical Enclosure

Electrical Enclosure

EV Battery Pack

EV Battery Pack

PV & Solar

PV & Solar

Filter Housing

Filter Housing

Plastic Enclosure

Plastic Enclosure

Explosion Proof Cabinet

Explosion Proof Cabinet

Cleanroom Door

Cleanroom Door

Household Appliance

Household Appliance

The automatic drum dispensing system can accommodate up to 55 gallons (approximately 200 kg of materials), featuring automatic cover lifting and an automated system for feeding, stirring, and supplying materials, all powered pneumatically for energy efficiency.

The water-cooled storage tank is an innovative storage device designed specifically for prolonged high-heat settings. It can keep the gasket sealants and adhesives at desired temperatures, thereby ensuring product quality and consistency.

Leveraging our extensive expertise in formed-in-place foam gasket equipment manufacturing, we specialize in creating bespoke automatic gasketing & sealing lines. These are fully customizable to match your specific requirements in terms of travel range, gasket width, pace, and foam gasket type, etc., ensuring a solution that is perfectly aligned with your production goals.